Improved Shea Roaster

Ghana

Shea nuts are grown and harvested across much of West Africa. It is a multi-billion-dollar industry, and most of the processing is done by women who get paid very little. The current process for roasting shea kernels needs improvement to address significant health and environmental shortcomings, including low fuel efficiency and high particulate emissions, and inconsistent roasting quality.

Since this project began in May 2018, we have:

- Designed close to one hundred iterations and built dozens of prototypes

- Performed hundreds of laboratory and field tests

- Gathered user feedback from over 1500 women

- Transferred the technology and the manufacturing to Northern Ghana as part of our Pilot Phase in 2022

- Partnered with SAYeTECH Limited, in 2023, to transfer the technology and take on the full production of the shea roaster as a new product line

- Granted USAID Market Systems and Resiliency Activity

- Produced over 50 BDL improved shea roasters in Ghana

- Impacted over 3000 women, benefiting from the technology so far

The next step for the Shea Roaster Project is to continue supporting SAYeTECH in the full scale production of BDL Shea Roaster, while raising funds to:

- Subsidize the cost of roasters to make them more accessible

- Improve manufacturing systems and equipment with SAYeTECH

- Develop a second-generation improved shea roaster with the lessons learned from our initial implementation, emphasizing on some or all of the following: Improved design for manufacturing, reduced cost of materials, larger capacity drum, etc.

Additional Partners/Sponsors: ASME Innovation Showcase Award Winner 2023. UN Innovation Competition Winner 2024, .ORG Impact Award Finalist 2023

To stay up to date with the project sign up for our mailing list or follow along on our team blog!

Support the Shea Roaster Project today!

"I am worried this job will give me lung infections due to the I smoke am exposed to."

—Fulera Imoro , Tuntieya Shea Butter Processing Centre - Jisonayili

Project Goals

-

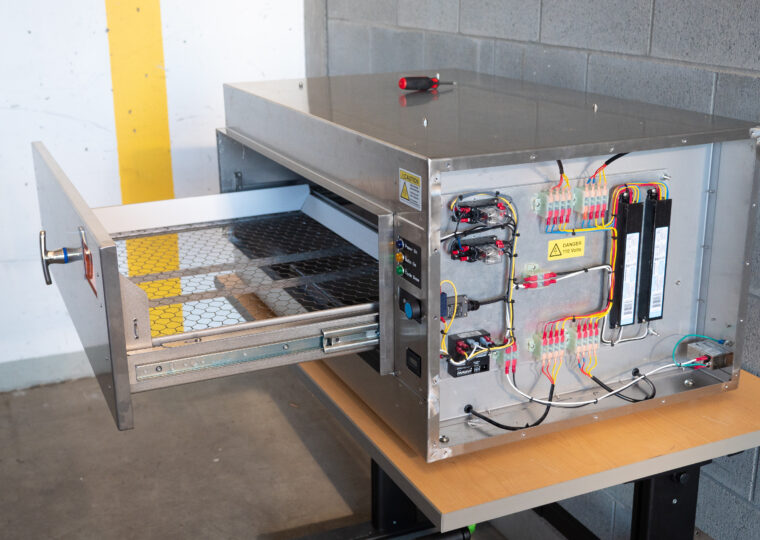

Improved Roaster

Save up to 90% wood use when switching to shea cake residue fuel

Save up to 70% harmful emissions to users (PM2.5)

Save an estimated 0.68 etCO2 per ton of butter produced

Provide more than double the thermal efficiency of traditional rotating shea nut roasters

Last more than three years in heavy use

Roast shea faster and produce higher quality butter

-

Alternative Fuels

Designed to eliminate most, if not all, wood consumption as fuel source.

Inline with Ghana's goals to move towards 50% LPG usage by 2020 (goal created in 2013).

Improve the use of shea cake or briquette, the biomass byproduct of the shea butter process, as the main source of fuel

-

Ergonomic Drive Mechanism

Mechanism to make it safer and easier for women to rotate the roaster drum.

Rotation aided by treadle design.

Partners & Sponsors

USAID

ASME

Global Shea Alliance

Baraka Shea Butter

Winrock International

TechnoServe

Curious about this project?

Browse our FAQs or contact us with your questions.

Want to see more projects like this?

Share or donate now to support our work saving the environment and empowering people in the developing world