Third time's a charm?

Brandy Tang

August 16, 2021

I spent most of the night before the trip packing what I needed for Ghana. Having had the trip cancelled twice before, I was putting things off till the last minute. It was a decision that was starting to turn into regret. When I finally finished and my head hit the pillow, there was still a part of me that thought something big was going to cancel our flight once more. What could it be? Prehistoric irradiated monsters? Giant Meteor? All the bathrooms on the plane malfunctioned? These were my last fleeting thoughts before weariness overcame me.

Actually, the bathrooms didn’t all malfunction until the end of our trip.

Today was the day! But disaster had struck! I forgot to do the dishes at work! I booked it back to the office to clean up my mess. With the mini crisis adverted, I felt ready for the day. Claire had graciously offered to safely ferry us to the airport. And when Jeremy and I loaded up our luggage, we were finally off.

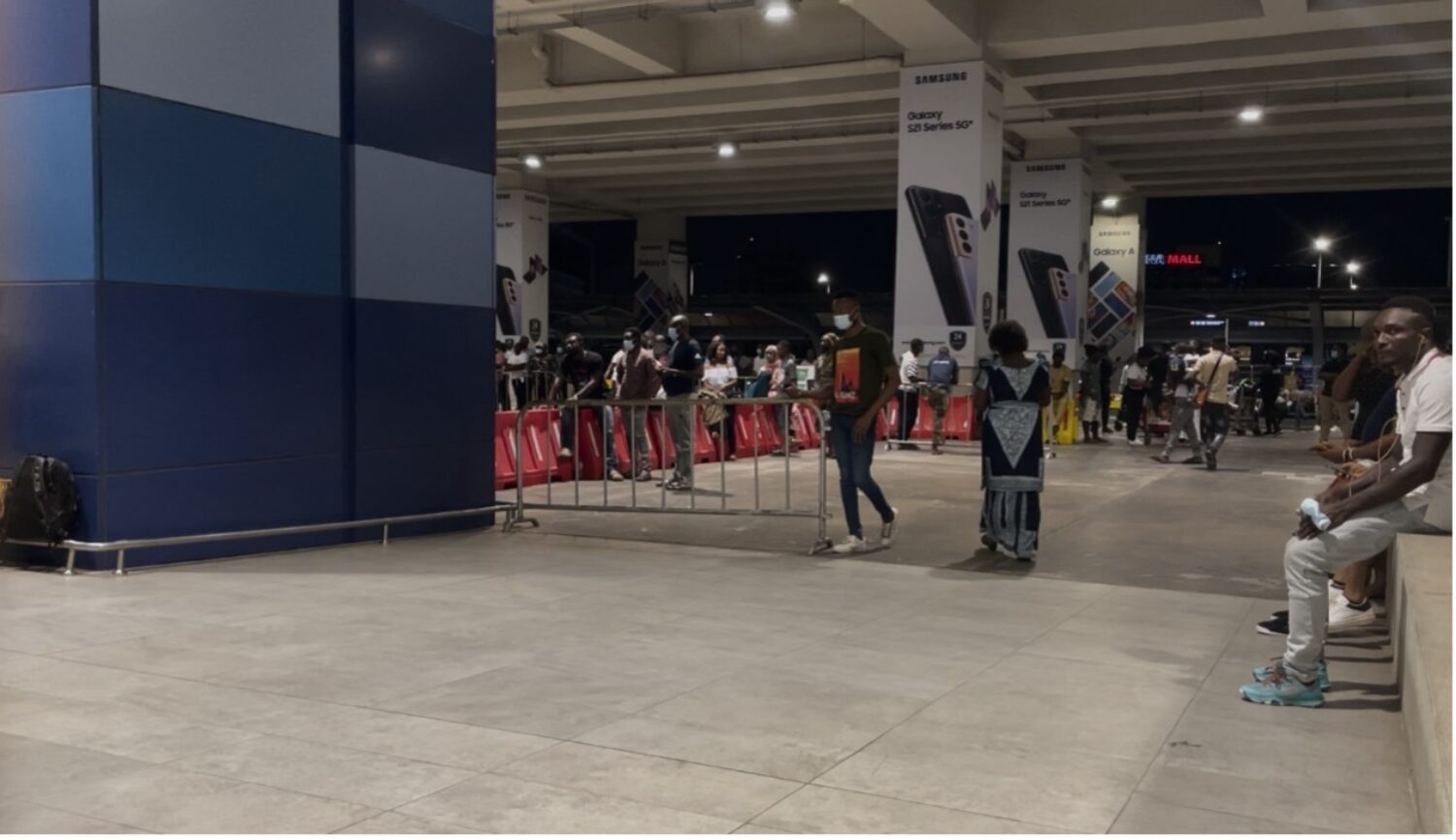

Hairdryer. That was my first impression of Ghana stepping out from the air conditioned Kotoka International Airport out into the night. A friend of mine described Phoenix, Arizona as living in a hairdryer. At the time I didn’t understand what she meant till that day. The heat was quite palpable. Of course, this was coming from someone who’s spent most of her life in the coolness of the Pacific Northwest. I used to joke with a friend that I wouldn’t get excited about the trip till I stepped on Ghanaian soil. And here I was, sweaty, tired and filled with nervous excitement to see how things would unfold.

Kotoka International Airport

For the next couple weeks, we spent our time meeting different manufacturers, organizations and key players in both the Shea Butter and cookstove spaces across Ghana. While working at Burn Design Lab, on Vashon Island, there’s a certain level of detachment between our work and the reality for those who we try to serve. We consistently hear the buzzwords, learn about the statistics and reasons why our work matters. It was hard to imagine sometimes that me starting fires was helping decrease deforestation in any way. But having the chance to interact with people who have spent years actively trying to solve these challenges that we’ve only seen on paper really put things into focus. Their passion, their dedication and drive were inspiring.

The last week of our time in Ghana was spent in Tamale to test out the Shea Roaster Prototype. Our first hand-crafted shea butter co-operative was the Tiyumba Shea Butter Centre. Things didn’t go smoothly at first, but hey what ever does the first time around? The drum handle broke and shea nuts were leaking from the drum. Almost all that could go wrong did but the shea nuts were roasted to a satisfactory amount. We came out of that first round of testing with a better understanding of the prototype and testing procedure.

After we left the coop we located a local machine shop that had welding capabilities. With their help we were able to repair both the door and handle of the drum as well as add additional modifications to the frame of the roaster. These adjustments greatly improved the success of the prototype in subsequent tests.

Our next co-op was at Pagsung. And the prototype performed beautifully and everyone was thoroughly impressed. It was a such a nice day out that there were wandering chickens and goats about. We spent a good chunk of time helping chase them away from the drying shea nuts. I couldn’t blame them though the freshly roasted nuts smelled like velvety chocolate.

The next day we visited the Yumzaa co-op. At the last two co-ops the weather lent us breezy conditions that any smoke from traditional roasters was usually blown away from us. It was not the case that day. We were roasting under a large pavilion with shea cake briquettes. Unbeknownst to us, the briquettes were not properly dried yet. This resulted in a lot of smoke emitting from the chimneys of the prototype. And because we were under a roof all the smoke that came out eventually fell back down unto us. We switched to just wood fuel after a while and that almost eliminated all the smoke. From a visual inspection there was an obvious reduction of emissions from the prototype compared to the current roasting technology that was being used. This difference was greatly illustrated when we were testing their roaster. A large amount of smoke was billowing out of just one of their roasters. At some point a couple more roasters were lit to roast shea nuts. The whole area was quickly filled with smoke, like a sickly fog descending on us.

I imagine that the facility wasn’t in full operation but it was already alarming what the working conditions were. And these women willingly come in to work here, despite the consequences to their health. Our last site had us unexpecting returning to the Pagsung coop. There were some hiccups but we eventually finished the last of our testing. We decided to leave our prototype with them and they were very excited by the prospect. As a sign of appreciation, they gave us an impromptu dance performance. It was very unexpected and a really humbling experience. I can’t remember anything that I would have danced with joy for in receiving. But the smiles I saw that day is something that will stay with me for a long while

That night I crushed the last of the shea nut samples by the light of the moon and my phone’s flashlight. I attracted some attention of a couple who were also sitting out in the parking lot of the hotel. Their curiosity must have been piqued when they saw me smashing sandwich bags with a hammer. They asked what I was doing and I explained about our trip, the testing and Burn Design Lab. The couple was from Ghana but, they like me before I started work at Burn Design Lab, were unaware of how much work went into making shea butter.

We had purchased some bars of shea soap from the Pagsung coop and holding that 2-in x 3-in bar I have some hesitation in using it. So much work and effort, that I only got to catch a glimpse of during this trip, was resting in the palm of my hand. At some of the co-ops we saw some kids and even babies hanging out as their mothers were working. It reminded me a lot of my sister and I, our cousins too, growing up and watching our own parents working at the family restaurant after school. It wasn’t glamorous and it was strenuous work. Continuing to work day in and day out, even if it was detriment to their own health. I am in awe of these women, because I see a lot of my own family in them. The very same sacrifices made if it meant they could provide for their families. And if it’s possible with this Improved Shea Roaster for us to relieve some of that burden, it’ll be all the more worthwhile.

This trip was an experience. This was my second time ever to travel internationally. I’ve met a great deal of unique individuals, seen some captivating sights and obtained a nice farmer’s tan (it’s since faded). One of the things that this trip has really taught me is to be more flexible. A lot of logistical things went wrong and, in the moment, it was disheartening. Prototype testing had its own hiccups along the way as well. But this is the nature of field testing. As the lab manager at Burn Design Lab, it’s my job to test cookstoves. I have a lot of control over how tests are run. The “weather”, type of fuel, the manner in which the stove is tended, etc. are all carefully monitored and adjusted. The stove performs in a very orderly and idealistic environment. If anything breaks down I can just walk across warehouse and have it repaired But, ideal conditions are not what the final iteration of the shea nut roaster will experience over the course of its lifetime. We could have never predicted or simulated a distracting goat, a particularly windy day or using wet shea briquette fuel in our lab. However, these hiccups gave us insights into the conditions that we will have to successfully overcome. Having the opportunity to observe and talk with the women on their interaction with the roaster was invaluable as well. In the lab a motor was our user rotating the drum and we would have inevitability missed that the size of the drum might be an issue. And that’s why our trip was a success. This wealth of information we were able to collect, which we wouldn’t have been able to obtain before, will inevitably help us design the best shea nut roaster. A shea nut roaster that not only performs well but is a true collaboration between us and the people we try to serve.